Imaging tubes: Critical Consumables

Why these essential parts underscore the importance of predictive services

When it comes to medical devices, every part and detail matters. Equipment is more than any single component or individual part, and equipment’s uptime is greatly influenced by the ability to have a predictive maintenance service plan in place. When it comes to CT equipment, there’s perhaps nothing more critical than the tube being used with it. An X-ray tube failure is easily one of the imaging department’s greatest fears, because of the cost incurred by the downtime generated, the impact on the hospital workflow, and the inability to deliver care on time.

The impact of unplanned downtime

Tube or X-ray generation failures are the biggest causes of unplanned downtime for computed tomography (CT) and radiology systems. These failures can derail an organization’s entire care operation and affect scheduled and emergency exams—exposing an organization to unnecessary risks and loss of revenue. Plus, unplanned downtime can cause undue stress for patients anxiously waiting for a significant diagnosis or treatment plan. Such events could potentially drive overtime, staff stress and fatigue to recover missed examinations. Even when equipment is running smoothly, the fear of tube or X-ray generation failure can create a stressful environment for clinicians to operate in. This is especially true when critical CT examinations are required, such as for a stroke or emergency purposes when patient care is critical. In departments where the risks are high, peace of mind is paramount when imaging a patient. The focus should always be on the care, not on managing equipment.

Putting together an equipment service plan

Figuring out the most appropriate equipment service plan for your critical equipment will help you limit those variables, reducing stress on staff, avoiding disruption in patient care, and protecting revenue by reducing unplanned downtime. Predictive maintenance services and quality, original equipment manufacturer (OEM) parts are solutions that can support your organization’s overall performance and patient care.

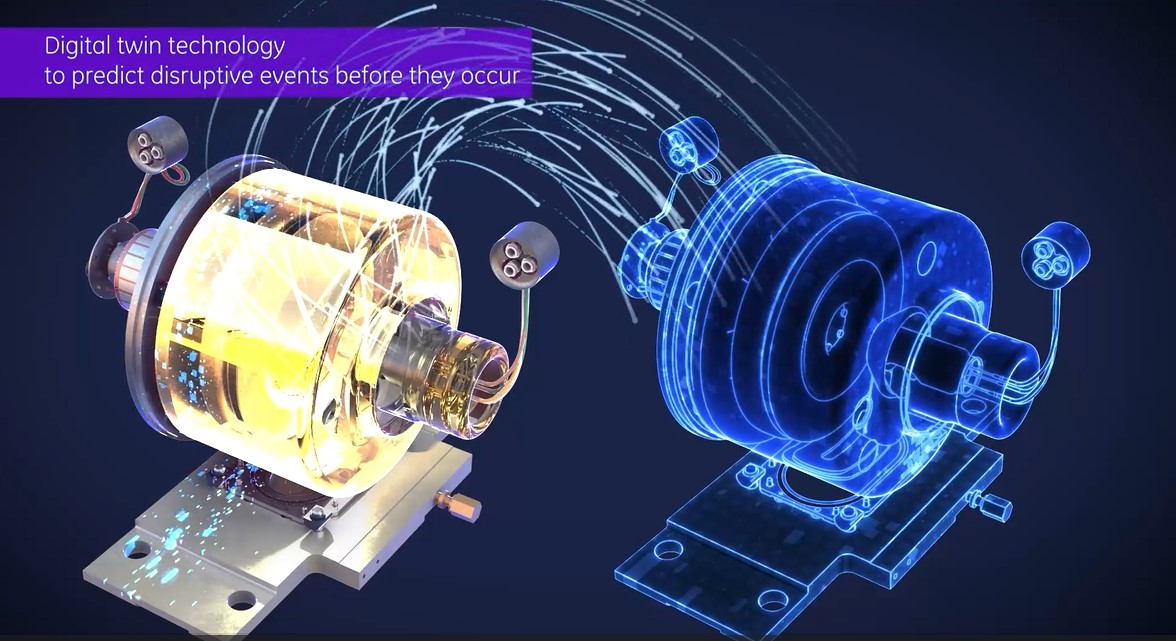

You might be asking: “What exactly is predictive maintenance and how does it work?” Leveraging AI and the power of machine learning, predictive monitoring anticipates impending failures in the X-ray chain generation such as X-ray tubes, HV tanks, inverters, or control boards before they occur, thus preventing unplanned downtime and reducing disruptions.

For example, Tube Watch is a predictive solution from GE HealthCare that’s designed to monitor and predict for the whole X-ray generation chain (including the tube) when a failure might happen. This helps to significantly limit unplanned downtime because it monitors the health status of your equipment and helps coordinate replacement part installation or needed maintenance at the most convenient time in your schedule. It’s designed to accurately predict failure—giving enough lead time before disruption occurs so that corrective actions can take place in a timely manner.

Full contract coverage that includes predictive services helps standardize your budget as well. In this case, you would plan for the consistent cost of the service and not for expensive parts and labor that could vary dramatically.

The proof is in the parts

The other way you can support your equipment service strategy is through the use of quality, OEM parts. The original manufacturer of your equipment will understand your system better than anyone else and can provide parts specifically designed to optimize performance. Third-party manufactured parts claim to have the same performance as an OEM part at a more affordable price, but it’s not that simple. Third-party parts offer a quick way to save money, but there are long-term risks associated with these products.

OEM parts undergo rigorous quality testing to match the standards of utility, performance, and reliability of a machine’s original parts. High-grade imaging equipment has specific nuances and requirements, and using anything other than OEM parts or accessories with your equipment can potentially impact performance.

The highest quality parts, proven and backed by an OEM, are a surefire way to ensure you’re delivering the best in patient care. Investing in a long-term relationship with your OEM, rather than a one-off purchase with an alternate part manufacturer, is a commitment that saves you in uptime and equipment longevity.

Simply put, you get what you pay for.

Maximizing uptime

Unplanned downtime leads to stress and potential loss of revenue. However, investing in OEM parts and comprehensive contract coverage including predictive maintenance services delivers peace of mind. It’s an investment into creating a better working environment for clinicians, allowing them to have full confidence in the systems. You’ll be able to anticipate downtime and plan around it, and you’ll know your equipment is operating at peak performance for the long haul. Patients, especially in emergency departments or critical care units, are counting on you and your equipment. OEM parts and predictive maintenance will ensure that your clinicians are ready to support them in the most critical moments.

You will also have more mental capacity to focus on delivering better patient care because you’re not dealing with unplanned downtime. Your patients will also experience a difference in streamlined, quality care. They likely won’t be looking for other healthcare providers because they’ll trust your operation and appreciate the consistent, reliable care they’re receiving— preventing “patient leakage” and keeping them in your system.

Equipped with quality. Prepared for downtime.

When it comes to imaging equipment, the combination of OEM parts and comprehensive contract coverage with predictive maintenance service helps you proactively address issues and perform at the optimum level. Your budget will become more predictable, your unplanned downtime will decrease, and you and your staff will have a better overall workflow experience. The stress from the potential fallout of tube failure is a difficult challenge for anyone, but the intersection of quality parts and predictive services is an effective, pragmatic solution to take your care to the next level.